ABOUT LIANHE SOLUTION

Shenzhen Lianhe Innovation Technology Co., Ltd.

A global source factory for OEM customization of CNC precision parts.

With 20 years of deep expertise in CNC precision machining, we specialize in providing global customers with high-precision, full-process OEM customization services for parts. Our business spans core sectors including robotics, drones, Al terminals, industrial intelli- gent equipment, aerospace, automotive parts, and medical devices. Our service network extends across Europe, America, Japan, South Korea, and other countries and regions, earn- ing the trust of global clients through exception- al quality and efficient service.

How Numbers Define Us

Manufacturing Details

Company History

Company Establishment

Shenzhen Lianhe Innovation Technology Co., Ltd. was officially established, embarking on a path of in-depth development in the field of CNC precision machining, focusing on the R&D and manufacturing of precision components.

Business Expansion and Technological Accumulation

After five years of development, its technological strength gradually improved, and its business began to cover domestic robotics, industrial intelligent equipment, and other fields, laying the foundation for subsequent global expansion.

ISO9001 Quality Management System Certification

Following the ISO9001 quality management system, meticulous quality control was achieved throughout the entire process from raw material procurement to finished product delivery, significantly improving product quality stability and enhancing market competitiveness.

Global Service Network Established

A service network covering Europe, America, Japan, South Korea, and other countries and regions was formed, establishing a global source factory for CNC precision component OEM customization and building a brand reputation in the international market.

Technological Breakthroughs and Multi-Sector Coverage

Achieved new breakthroughs in high-precision CNC component manufacturing technology, deeply covering core areas such as robotics, drones, AI terminals, aerospace, automotive parts, and medical devices, becoming a key partner for leading clients in multiple industries.

Process and Equipment Iteration and Upgrades

Continuously invested in advanced production and testing equipment such as CNC machining centers and coordinate measuring machines, further optimizing core manufacturing processes, surface treatment processes, and material selection to provide global customers with more efficient and precise customized solutions.

Manufacturing Process

Covering the entire process of CNC precision machining, mold making, injection molding, stamping, assembly, inspection, etc., we can customize precise process solutions according to customer needs and provide professional technical empowerment.

Raw Materials

Starting with premium-grade aluminum, steel, plastic, our cnc components promise unmatched durability and resilience, ideal for long-lasting solar applications.

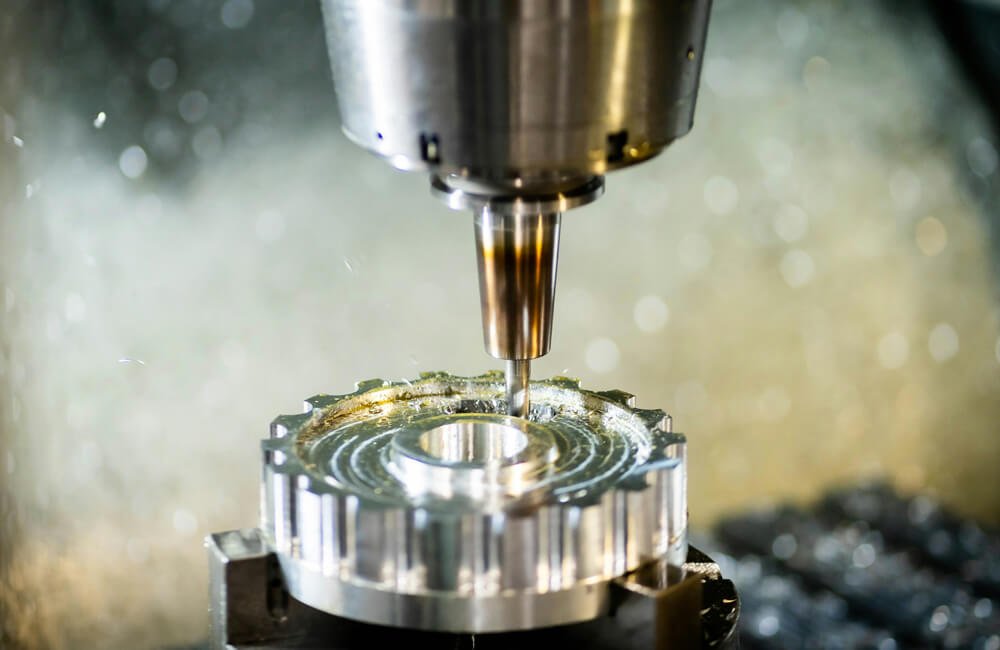

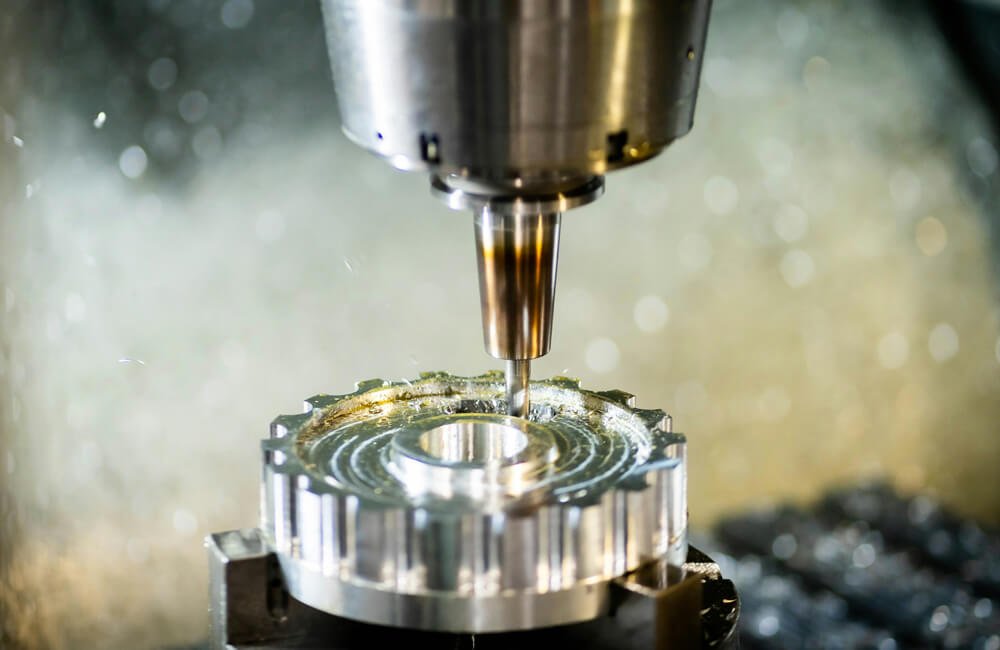

CNC precision machining

We carefully source high-grade metals, seals, and other certified materials, ensuring consistency, strength, and compliance with fire safety standards before entering the production line.

Mold Making

Specialized machines shape and refine the control button, maintaining accuracy and smooth operation, ensuring reliable activation during emergency fire protection situations.

Injection Molding

The valve cover is precisely molded, machined, and finished, providing strong protection and a secure housing to withstand high-pressure conditions in fire protection systems.

Stamping

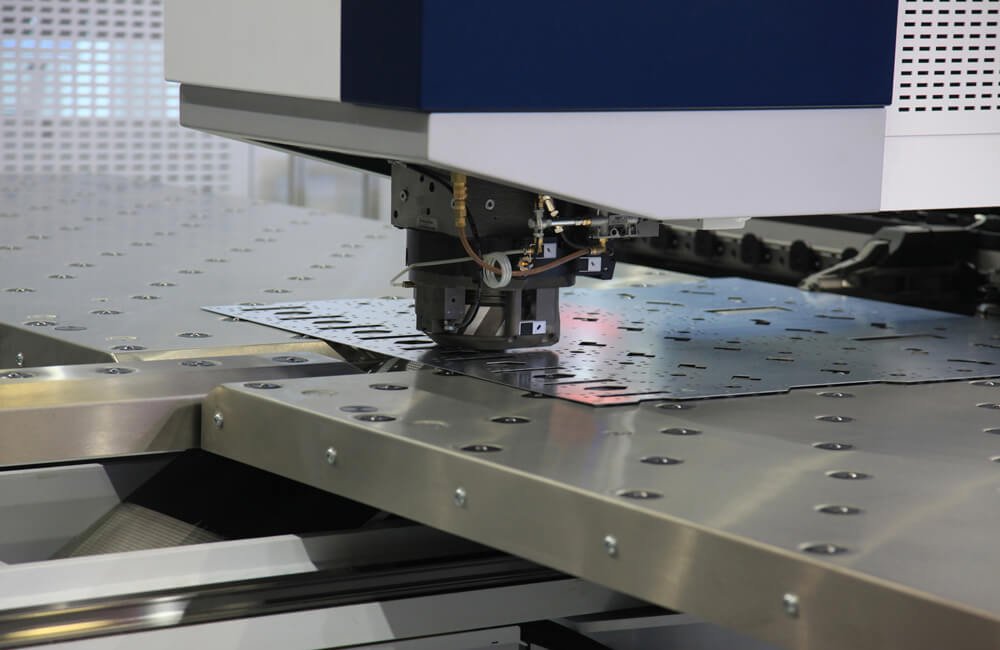

Each unit undergoes rigorous water pressure testing, simulating real-life emergency conditions to verify strength, leakage prevention, and reliable performance under extreme pressure.

Assembly

Products are coated with anti-corrosion, heat-resistant spray paint, ensuring long-lasting durability, improved aesthetics, and protection against environmental wear in challenging fire safety environments.

Inspection

Final assembly integrates tested and coated components, producing a complete unit that meets strict performance and safety requirements before entering the market.

Packaging & Shipping

Efficient loading and expedited shipment processes mean your high-quality CNC Machining parts are delivered swiftly and safely, right to your doorstep.

Surface Treatment Processes

Offering electroplating, anodizing, spraying, sandblasting and other diversified surface treatment options to meet the needs of different appliction scenarios.

Electroplating

Anodizing

Spraying

Sandblasting

Polishing

Heat Treatment

Materials

Adapting to the characteristics of multiple industries, the materials include

Metal

Aluminum Alloy, Stainless Steel, Brass, Red Copper, Titanium Alloy, High-Strength Alloy Steel, Medical Stainless Steel

Non-Metal

POM, PEEK, Teflon, Carbon Fiber, Various Engineering Plastics

Advanced Production & Inspection Equipment

Production Equipment

CNC Machining Centers, CNC Swiss-type Lathes, CNC Lathes, Turning-Milling Compound Machines, 3-axis/4-axis Machine Tools. Possesses high-precision, high-efficiency metal cutting capabilities, capable of complex processes like milling, drilling, boring.

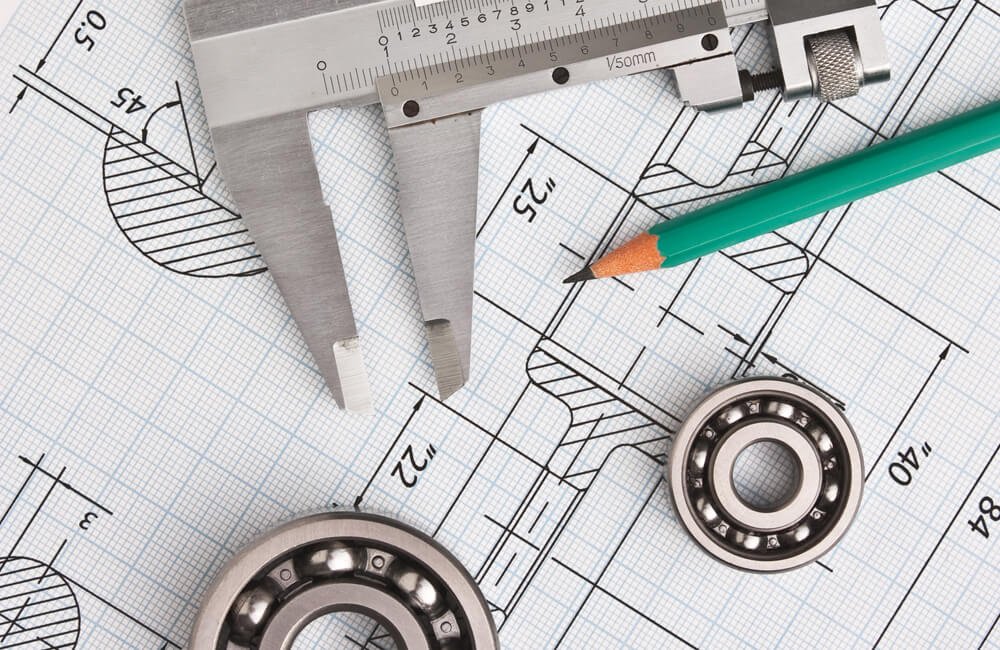

Inspection Equipment

CMM, Optical Measurement Systems, Hardness Testers, Material /Testingws Machines, Surface Roughness Measuring Instruments. Conducts comprehensive dimensional inspection of product precision and quality, ensuring delivered products meet standards.

FAQ

Most Popular Questions

1. Are you a factory or a trading company?

We are a factory company with our own factory located in Fujian Province. I have 15 years of experience in the fire protection industry

2. Why did we choose you? What advantages do you have?

We have an independent R&D team, a professional production and sales team, strong production capacity, strict product quality control, competitive prices, and comprehensive services. Small orders are also acceptable.

3.What is the payment method?

We accept wire transfers, letters of credit, Western Union, PayPal, and credit cards.

4. Can you customize products according to the customer's design?

Of course, OEM and ODM are acceptable to us, and you can directly mark the customer’s brand on the surface of the product.

5.What is your delivery time?

Delivery will be made within 10-30 days after receiving the deposit. According to the quantity.

6. What is the sample fee?

The sample cost and shipping fee need to be borne by you. When you reach the quantity based on the sample cost and total order amount, we will refund the sample fee and shipping fee.

7. Any inquiries will be replied to within 24 hours?

We can do it through email skype、 Communicate through WeChat, WhatsApp, and phone.

8. How do you ship the products?

And we also work with DHL, TNT,UPS,FedEx,EMS, China Airlines Post has strong cooperative relationships with many freight forwarders. You can also specify your freight forwarder.

9. What Certificates can you supply?

We have the certificates of : CCC, CE, ISO9001, ISO14001.